- Research & Instruments

- How we study - Our instruments and methods

- Instruments and Methods

- Workshops

- Mechanics Workshop

Mechanics Workshop

What is done in the mechanics workshop?

The technicians in the mechanics workshop work closely with the researchers at the Institute as well as their colleagues in the electronics workshop and the Landerhalle in order to ensure that the electronics are protected in the best possible way from the harsh environmental conditions in the sea. For example, they build racks, mounts, casings, battery housings, and (pressure-resistant) tanks for use in shallow water as well as for research projects in the deep sea. They develop prototypes and manufacture precision mechanical components according to sketches and samples in consultation with the scientists as well as their colleagues from the other workshops at the Institute.

But work on research equipment accounts for only about half of the requests that are submitted to the mechanics workshop. The technicians in the mechanics workshop also rebuild existing devices and repair laboratory equipment. Especially the latter is an important task because spare parts for laboratory equipment are often quite expensive and have long delivery times. They also support the Institute’s administrative staff and building services.

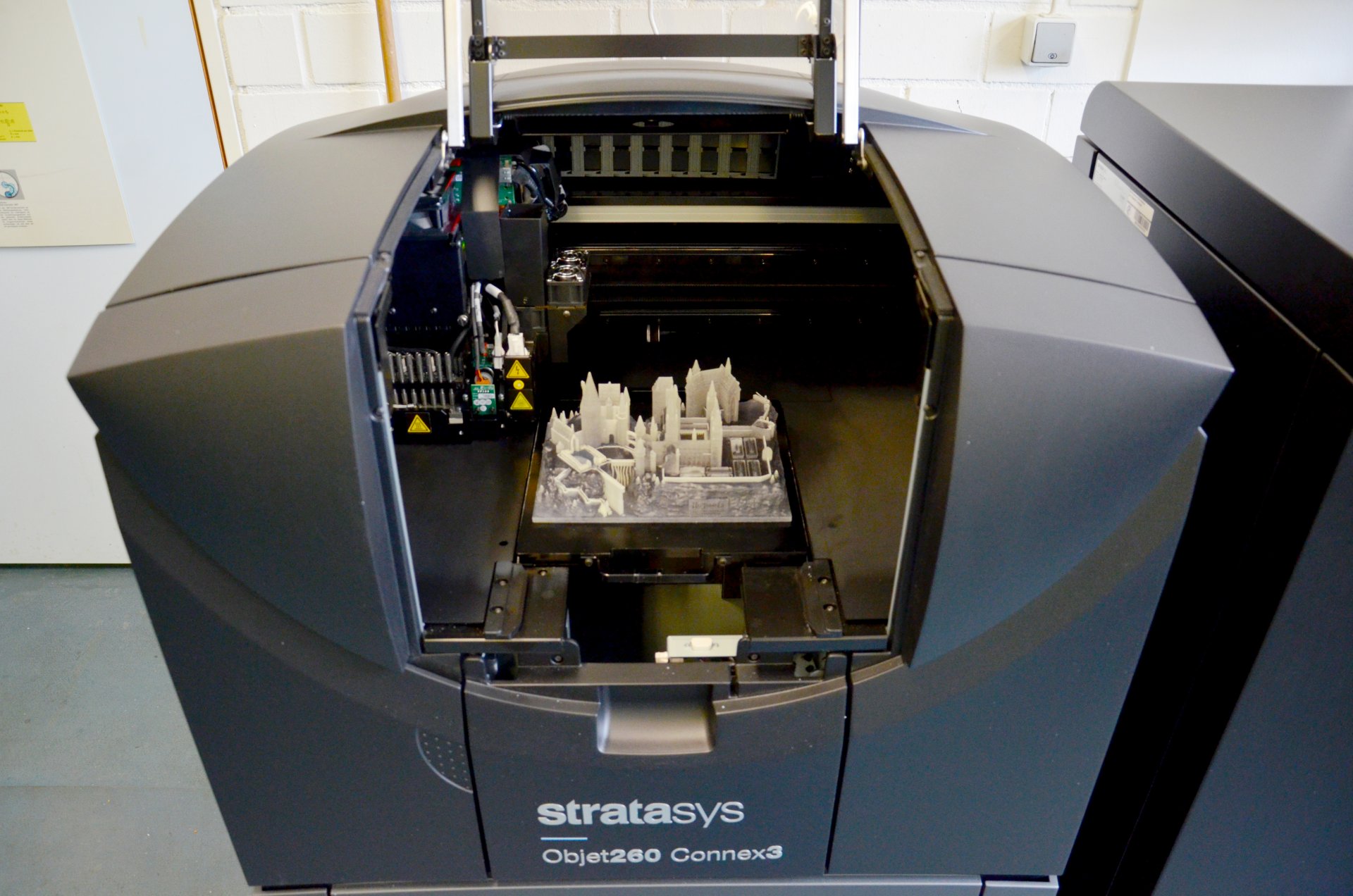

In the mechanics workshop, there are two technicians who can process all materials – from wood and titanium to plastics and glass. It all depends on the requirement. Turning, sawing, and milling are just as much a part of their craft as 3D printing.

How is research equipment developed? An example.

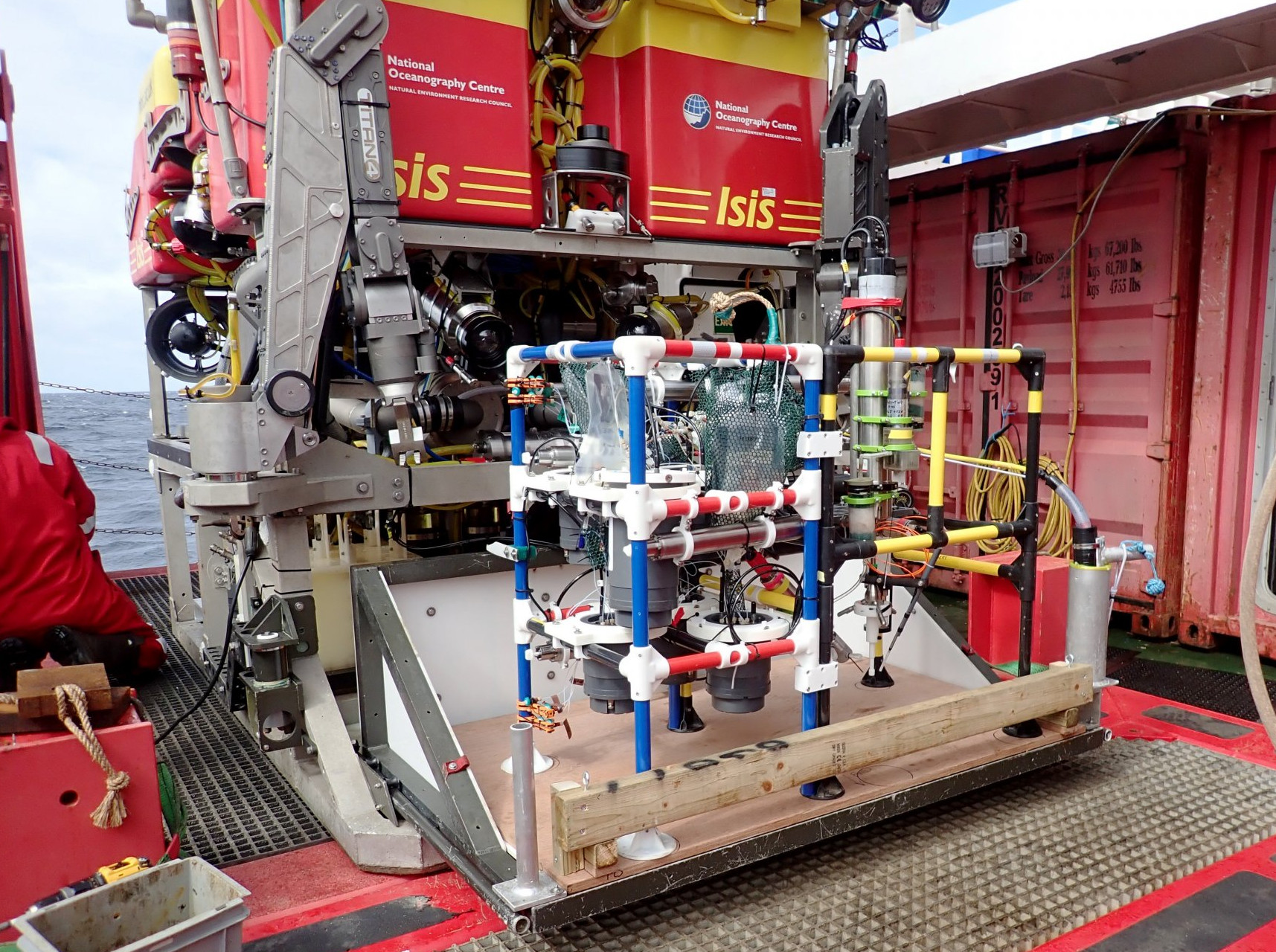

A typical example is when a scientist or even a colleague from the electronics workshop comes to the mechanics workshop with an electronic component and asks the technicians to make it fit for use in the sea. One specific case involved several sensors for measuring pH, turbidity, and temperature that were in two buckets and were to be used in the deep sea. The request: Build a frame that fits on an underwater robot (ROV). It had to be a certain size but was not allowed to exceed a certain weight.

However, after a few weeks, the research project had changed. The team now needed to mount another four buckets with sensors. Later, there was also a request to add a second unit that included a flow meter. In the end, the mechanics had built two racks that could be mounted side by side on the front of the ROV. They produced two of each so that measurements could be taken at two different locations at the same time. This is important in order to be able to compare data and exclude calibration errors.

This short example shows that tasks are always changing and adjustments to superstructures occur until shortly before an excursion. After all, the racks and mounts must be precisely tailored to the respective devices so that they can reliably deliver the required data. A huge responsibility. If something does not work properly in the field, the lengthy planning of trips can mean that important data cannot be collected, research projects are delayed or even fail altogether.

Who uses the mechanics workshop?

Especially scientists, technical staff, and building services. However, the mechanics workshop is open to all Institute staff.

Please direct your queries to

Technician

MPI for Marine Microbiology

Celsiusstr. 1

D-28359 Bremen

Germany

|

Room: |

1306 |

|

Phone: |

Technician

MPI for Marine Microbiology

Celsiusstr. 1

D-28359 Bremen

Germany

|

Room: |

1305 |

|

Phone: |